The German Navy is taking another important step into the future with the new emergency rescue centre. The focus here is on modernisation and efficiency.

The loss of the Marine Rescue Centre (Merz), which was part of the FRANKFURT AM MAIN task force supply unit (EGV), in 2015 due to a major fire in a shipyard hall made it necessary to procure a new one. The development of the new rescue centre is based on the experience gained with the container modules Naval Rescue Centre I and II in technical cooperation with the BERLIN and FRANKFURT AM MAIN task force supply units since 2002. The rescue centre is now integrated into a deckhouse permanently connected to the upper deck and the ship's superstructure and provides medical care level 2 as part of the maritime rescue chain. This level comprises initial emergency surgical measures with subsequent stabilisation of the patients and the aim of transferring them to a higher level of care on land.

In order to understand the advantages of the new development of the mission rescue centre, it is essential to look back at the past. Since 2002, the German Navy has had two naval rescue centres (Merz I and II) in containers as pre-hospital medical care facilities on board the task force supply ships BERLIN and FRANKFURT AM MAIN for its task forces.

The commissioning of this medical component, which was completely new in German naval history, closed the gap between the initial medical care provided by the original on-board medical facilities of the combat ships

(level 1) and the subsequent clinical care on land (levels 3 and 4).

The container system consists of 14 ISO containers each with a length of 20 and 30 feet. Together with the EGV, the Merz container system represents a logistical and technical system network. It consists of a combination of ship-fixed installations - the ship's hospital for self-sufficiency and a ward - as well as containerised functional units such as the operating theatre, intensive care and monitoring room, X-ray unit, laboratory, dental ward, pharmacy, central sterilisation unit and technical room, which function as an interconnectable deckhouse system and together form an active network with a capacity of 43 beds. The containers and their technical interfaces are designed for the ship, but can be operated with electricity and water at a special shore installation site at the Wilhelmshaven naval base outside of operating times and during shipyard layovers.

The Merz is designed to provide initial surgical care for the wounded with two surgical teams (Damage Control Surgery, DCS surgery) and an extended post-operative care capacity. As part of the maritime rescue chain, the Merz acts as medical care level 2 in the unit. It is designed to provide medical support for the entire spectrum of maritime operations from low to high intensity, including national and alliance defence, and includes the ability to support special forces and specialised forces in the maritime environment.

The system network is of particular importance in initial operations. Here it represents an essential support capability in the maritime and joint force approach.

Layer by layer

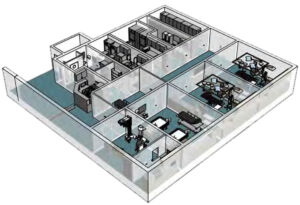

The lower container level, the so-called operating theatre level, forms the treatment level with two operating theatres, an intensive care monitoring room, an X-ray room and a dental treatment facility. In order to create rooms of sufficient size, two containers were connected several times by removing their respective longitudinal walls to form a working area.

The upper container level serves as a supply level with a clinical-chemical and a microbiological laboratory, a pharmacy, a sterilisation unit, a medical technology room as well as a production plant for medical oxygen (93%) using the molecular sieve process and one using the compression process for medical compressed air. Both the container complex and the bed ward on board the EGV are supplied with oxygen and compressed air centrally from here.

All supply and disposal lines for air conditioning, water and power supply are routed along the outside of the containers in compact modules to optimise the usable interior space. This offers advantages in terms of ease of maintenance and operational safety. Any damage to pipes or cables can be repaired quickly without causing damage to the rooms. However, it also has the disadvantage of being susceptible to the forces of nature and seawater.

System with weaknesses

The 28 containers have to be regularly assembled and disassembled to check their hulls, which is only possible at the home base with a special land installation site. However, this assembly and disassembly wears out the sealing hoses between the containers, which then have to be replaced. The screw connections for the wall panels, floor and ceiling panelling are also affected by such wear and tear. New holes have to be drilled again and again to ensure the necessary hold. Some of the screws on the floor panels between the containers have already come loose several times and had to be tightened again.

It takes 28 days to establish operational readiness after the start of the first preparatory measures for setting up on board. The external supply lines and connections between the Merz and the task force supplier are exposed to the challenging influences of changing weather conditions at sea. But the containers themselves are also subject to these extreme conditions at sea, especially the underbodies and connectors.

Due to the lack of a fixed connection between the container module and the citadel and the resulting NBC gap, the NBC safety of the Merz containers is inadequate. The transitions to the deck levels from the outside therefore do not provide any NBC protection. The containers themselves are only protected for a limited period of time, for example because personnel have to leave the container or interventions are cancelled.

In addition, the container levels are not connected to each other. Surgical instruments that need to be reprocessed must therefore be transported from the lower treatment level to the upper supply level outside the containers, which exposes the instruments to sea air for a short time.

Finally, patient transport from the citadel to the treatment level is also made considerably more difficult by the coaming and opposing bulkheads and is only protected from the outside by a temporary steel casing. However, this will warp at sea in the long term and there is also a risk of leaking connections.

Fire in the Merz

The Merz II assigned to the FRANKFURT AM MAIN task force provider was destroyed in a major fire in a shipyard warehouse on 22 February 2015. The individual containers of the system were undergoing scheduled shipyard repairs. 25 of the 29 containers, all of which were functional medical containers, were destroyed or severely damaged, including the large medical equipment that had not been removed. With the loss of the container module, the navy now only had one operational naval rescue centre. The loss of the rescue centre caused by the fire resulted in a capability gap that was to last for around seven years.

New and integrated

BAAINBw S5/S5.1 was already able to present four options for Merz replacement procurement on 31 March 2015. Pure replacement procurement was ruled out under the applicable procurement guidelines because the original product could no longer be realised. The only alternative was therefore a replacement procurement via a product modification with the requirement that new, innovative realisation options would open up to regain the capability without having to go through the extensive procurement procedure.

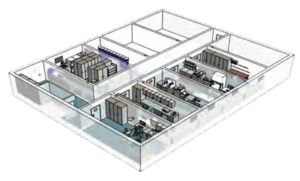

The decision was made to abandon the principle of modularity with individual containers and to combine the functional areas of the rescue centre in a deckhouse permanently connected to the task force provider. This integrated Marine Rescue Centre (iMerz) offers the following advantages:

- Closed outer skin (environment, EMC, insulation, ABC)

- Free room design independent of the container dimensions with improved room layout and optimised medical treatment processes

- Elimination of assembly and dismantling

- Minimisation of usage and maintenance costs

- Centralised energy supply including an uninterruptible power supply

- Production and preparation independent of the ship

- Fixed transition from the EGV deckhouse to the iMerz

- Direct connection between the EGV and iMerz wards via a lift

- Transition between B- and C-Deck within the iMerz

- Full ABC protection

Due to the requirements of the replacement procurement modalities, the functional units of the Merz container module were retained, but modernised and rearranged by optimising the handling processes.

Here are some examples:

- the new development of the sterilisation system and its relocation to the operating theatre level B deck instead of the previous C deck

- the X-ray unit

- patient transport in the hospital bed from the ward to the hospital

iMerz and vice versa via a lift

- the internal connection of the deck levels via an integrated staircase

Operating theatre, sterilisation, patient care

Functional rooms with XXXXX

Construction of the new rescue centre at German Naval Yards Kiel (GNYK) began on 25 September 2019 with the start of firing of the outer wall segments of the compact deckhouse. The medical equipment was provided by Zeppelin Mobile Systeme (ZMS) during the course of construction.

On 16 March 2020, the shipyard suddenly decided to discard the two-storey shell that had already been built due to tolerances being exceeded and to rebuild it with adapted technology and design adjustments - with all the consequences of a significantly delayed completion of the project that cannot be specified in terms of time.

Before a new body shell was actually produced, the workshop drawings were fundamentally revised by the end of 2020 and any potential identified for improving product quality and functionality was utilised.

The assembly of the deckhouse and the pre-fitting with subsequent acceptance were to be completed by the end of July 2021. In April of this year, however, there was another dramatic cut in the progress of the project. The parent shipyard Nobiskrug filed for insolvency, which is why German Naval Yards suspended further construction due to non-payment. It was not until September 2021 that a solution for the continuation of the project was developed as part of the insolvency proceedings and work was resumed.

Laboratories, pharmacy, dentist, medical technology

In April 2022, the construction of the deckhouse was completed and further progress was made on equipping the functional rooms with furniture and permanently installed medical equipment, for example for sterilisation and the supply of medical gases.

On 23 May, the task force provider FRANKFURT AM MAIN received the deckhouse from GNYK. After completion of its permanent connection with the deck superstructure of the EGV and completion of the interior fittings of its functional areas, the ship left the shipyard at the end of July. Functional tests of both the iMerz and the newly created technical network are being carried out.

The Rescue Centre Sea (RZSee) of the near future is a permanent technical network between the iMerz deckhouse module and the platform of the task force provider. It is characterised by the following innovations compared to the previous container solution:

- Integration of a permanently installed Merz compact module (iMerz)

- Modernisation of ship operations

- Improved logistical supply

- Modernisation of the rescue equipment through the integration of modern brushes

- On-board integration of the Sea Lion helicopter

Jörg Dustmann