Following the publication of the article "The art of shipbuilding" in issue 9-2021, the editorial team received enquiries from readers who wanted to know more about swath technology. In his article, Carsten Wibel from Abeking & Rasmussen explains the principles and advantages of Swath.

A ship designed according to the swath principle should move little, even in heavy seas, and the crew should only have to cope with low accelerations. The special feature is the reduced waterline area of the two hull halves, hence the term small waterplane area twin hull. Almost 100 boats and ships worldwide have been built according to this principle to date - 26 of them at Abeking & Rasmussen (A&R) in Lemwerder.

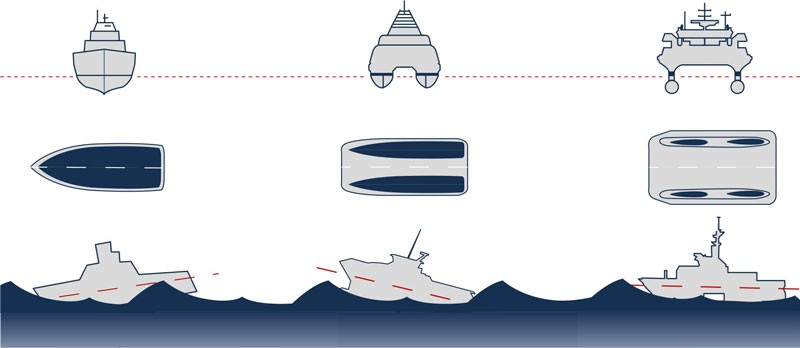

It is a truism for all seafarers that swell causes ship movements. Physically, this occurs exclusively in the waterline area via the displacement change caused. The buoyancy bodies are therefore arranged deep under water in the swath principle. The ship's superstructure rests on supports called struts. Like submerged submarines, swell does not excite the swath buoyancy bodies. Only at the struts, with their small waterline area, can the swell stimulate the ship to move. The result is significantly reduced ship movements in heavy seas. When comparing different hull shapes, the differences are striking. The waterline area of swath vessels is significantly smaller than that of ships with single or double hulls.

The reduced waterline area means that Swath ships remain stable in the water even in rough seas. Graphic: A&R

A Swath with a comparable displacement has considerably lower acceleration than a monohull or catamaran of the same size. For the Swath class with a length of 25 metres, these are just a third of the comparative values of the other designs. Conversely, you would need at least a ship with three times the displacement to achieve the same values. Particularly with regard to the occurrence of seasickness or the possibility of carrying out certain mission-critical work on deck or inside the ship, these values can be decisive for the operational limits and capabilities of the entire unit. This applies to the transfer of pilots as well as to carrying out research or offshore investigations, patrols or military operations. one of the challenges in implementing the swath principle is weight management. If the weight of the ship changes, the required buoyancy changes. With single or double hulls, the hull dips lower in the waterline area. Due to the large surface area, the change is minimal. In the case of swath vehicles, this change in immersion is considerably greater due to the small waterline area of the struts. This is because only here can the buoyancy change and thus compensate for weight modifications. The ability to manage this factor professionally demonstrates the experience of the Swath shipyard.

One alternative is to compensate for weight changes by taking on or releasing ballast. Compensation through ballast water requires shipbuilding changes to the tank size, which in turn change the ship's weight. These modifications to the ship's weight must also be compensated for by correcting the buoyancy. In order to optimise the implementation of the swath principle, each weight change therefore requires multiple calculations of the buoyancy bodies. There are also limits to the adjustment due to stability requirements, speed and range specifications.

During the design phase, this optimisation can theoretically be repeated as often as required within the limits. Once construction of the swath vehicle has begun, the modification limits are defined by the design. During the work, precision manufacturing, low tolerances and constant weight control must ensure that the design specifications are adhered to.

26 Swath@A&R boats and ships are currently in daily service around the world. A total of three station ships and five transfer tenders are available in the German Bight. The two 60-metre station vessels ELBE and WESER, built in 2010, and the 50-metre station vessel HANSE offer accommodation for up to 50 pilots. The 25 metre long Swath@A&R transfer tenders transport the pilots reliably between the station ship and the ships to be piloted. Every year, DÖSE and DUHNEN (both 1999), WANGEROOG and BORKUM (both 2004) and GRODEN (2011) enable thousands of safe crossings, even in heavy weather. The Belgian and Dutch pilots and even their American colleagues in Houston, Texas, also rely on Swath@A&R stowing systems from Lower Saxony.

Planned minesweeper drone from A&R. Graphic: A&R

Another advantage for civil or military applications are the deeply submerged, torpedo-shaped hulls. They prevent air bubbles, which can interfere with sensitive measuring and localisation systems. The hydrographic Swath@A&R research vessel JAKOB PREI has been proving its worth for the Estonian Maritime Administration since 2012. The low accelerations also make it easier to deploy any type of equipment, whether civilian or military, manual or automated.

Between 2011 and 2014, five SKRUNDA-class Swath@A&R patrol boats were put into service by the Latvian Navy. An interchangeable 20-foot container is located on their forecastle. Various mission modules in these containers enable, for example, mine detection or diving operations even in rough seas.

The youngest and smallest member of the Swath@A&R family has so far only existed in the design computers: a drone that is almost nine metres long and weighs five tonnes. It can be operated manually, remotely or autonomously. Automated launching or retrieval of unmanned systems is also possible in adverse sea conditions - its sea behaviour is expected to be three times that of a monohull ship. The design takes into account the characteristics required for USVs in terms of weight, payload, speed and endurance for military or civilian applications.

Swath@A&R initially means considerably more: more design and calculation work, more control in weight management, more co-operation and coordination with component suppliers, more precision in production. But this is the only way to achieve the desired success - fewer ship movements due to a reduced waterline area.

Author: Carsten-Söhnke Wibel is Sales Director Special Vessels at Abeking & Rasmussen.

0 Kommentare