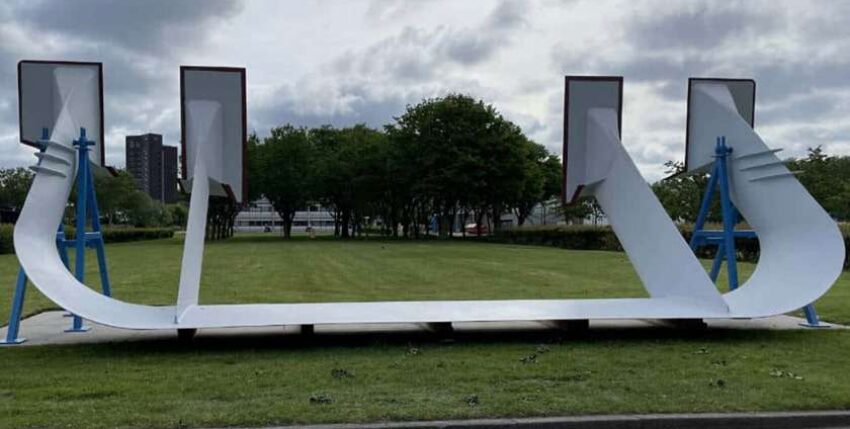

The first Hull Vane for the Royal Dutch Navy was delivered in Den Helder at the beginning of June 2022. This is a baffle plate to be fitted under the stern that makes ships faster and quieter, i.e. more efficient, while also improving their sea behaviour. This guide plate will be installed on the transom of the "HNLMS Groningen", one of the four 108-metre-long and, at 3,800 tonnes, frigate-sized "Holland" class offshore patrol vessels (OPV), at the beginning of 2023.

Development

In 2015, the Dutch hydrodynamics specialist Hull Vane BV, as patent holder, calculated in a study that the guide plate could reduce the annual fuel costs for a patrol vessel by around 13 %. The Defence Materiel Organisation (DMO) of the Dutch Ministry of Defence commissioned further research into the functionality and structural strength of the guide plate and the optimisation of the carrier's seaworthiness. This work was financed by the small Dutch company MIND (Military Innovation by Doing). Unusual, but a good example of how innovations for defence can be implemented through new processes.

Function

While a profiled wing generates lift on the "light" aircraft, the guide plate under the "heavy" stern generates a negative pressure behind the ship due to the accelerated water flow on its upper side, which reduces the stern wave - resulting in more propulsion with the same energy consumption. Due to the direct correlation between a ship's wave system and its propulsion power - wave crests are evidence of frictional losses due to unfavourable flow conditions on the hull - any reduction in the stern wave also reduces fuel consumption. This works in a similar way to a bow bulge, which reduces the bow wave and has a positive effect on the entire wave system of a ship.

Realisation

As a result of the performance optimisation study, the construction order was placed and the largest and heaviest guide plate ever built was completed at Hull Vane BV - which is now ready to be installed on the "Groningen" during the next shipyard laytime. According to the manufacturer, more than 40 such guide plates are now in use on a variety of ship types, which means that this technology can certainly be described as tried and tested and foreign navies are also following this project with great interest.

Tactical advantages

In addition to saving energy, which automatically leads to a reduction in CO2 emissions, the guide plate also offers tactical advantages for the ship. It will have a higher top speed with the same propulsion power while maintaining its trim across all speed ranges. Helicopter landings will be safer in rough weather and it is expected that launching and recovery of the fast daughter boat via the stern bay of the "Groningen" can be carried out with reduced risk. In addition, a smaller wake reduces both the noise level and thus the detection ranges under water, as well as the visual "wake" as a trademark for reconnaissance from the air or from space. Not entirely unimportant for a naval vessel, especially in times of war!

A plausible idea

The question remains as to why nobody realised this earlier? We will continue to follow the progress and report back.

Hull Vane is a trademark of Hull Vane BV, Wageningen, NDL.