Australia opens competition for world's largest non-nuclear submarine project - Since the Australian Department of Defence published its "Strategic Direction of the Future Submarine Programme" on 20 February this year, it has been clear that France, Germany and Japan are potential partners in the SEA 1000 project, i.e. the development and procurement of up to 12 new submarines for the Royal Australian Navy (RAN). Following a ten-month competitive evaluation process, one of the three candidates will be awarded the contract.

Ever since August 2008, when the independent "Submarine Institute of Australia" presented a comprehensive submarine report for the Defence White Paper published in 2009 under the Labour government, it has been internationally known that the influx of new submarines will increase from the mid-2020s onwards. Submarines is planned. SEA 1000 has thus been an integral part of security policy for six years and has remained so under the conservative coalition government led by Prime Minister Tony Abbott since September 2013. The fact that Canberra has only now announced its official procurement strategy for the "Future Submarine" (FSM) is due to political trench warfare, which will be discussed in more detail below. Accordingly, the Ministry of Defence will launch the competition after details were communicated to the three potential partners and their respective industry representatives at the beginning of March. The fact that countries and not companies are named is presumably due to a government-to-government agreement (G-to-G) under which the project is to be handled. The process is designed to ensure that Australian taxpayers' money is used to fund the future Submarine The aim is to provide the best possible skills and maximise the involvement of local industry.

According to the document, the country's maritime security and the protection of its trade depend on whether the timely delivery of the first FSM from the mid-2020s, when the decommissioning of the Submarines of the COLLINS class, a capability gap could be avoided. Beyond the 2040s, the new vessels would contribute to the defence of Australia and its interests with a lifetime cost of 50 billion Australian dollars (€35 billion). The government expects a significant amount of work during the construction phase of this, the largest defence programme in Australia's history, to be carried out domestically. This includes the integration of the Command, Control and Weapons Employment System (CWES), design oversight and land testing and will create at least 500 new high value jobs.

Potential partners involved in the competitive evaluation process will be expected to submit proposals on a rough design against the Australian capability criteria, options for design and construction (overseas, in-country or hybrid) including a labour, schedule and budget for each option and issues such as IPR protection. The announcement also contains the following key strategic requirements: Range and sea endurance like COLLINS; sensor performance and signatures (stealth) better than COLLINS; FüWES and heavyweight torpedo - jointly developed by the USA and Australia - are set.

In the announcement, the government emphasises that the domestic industry needs an international partner to optimise its project involvement. Canberra recognises that Australia's ability to design and build on its own is not sufficient, despite the highly sophisticated COLLINS class built entirely domestically between 1987 and 2003. After careful consideration, the Ministry of Defence selected France, Germany and Japan because these three countries have proven design and construction capabilities and are currently producing new submarines.

Immediately after the procurement strategy was issued, Australian media reported on and commented on the heated disputes in political, business and naval circles over Sweden not being considered as a potential partner. The official reason given by the Ministry of Defence was that although Sweden's Kockums submarine shipyard was Australia's partner in the COLLINS project and was also the "design authority" for these boats until 2001, it was currently unable to meet the test criterion of "ongoing construction programmes", as it had not delivered a new submarine for almost 20 years.

Ambitious performance parameters

The key strategic requirements, transferred to the specific capability profile of the FSM, result in extremely ambitious performance parameters, some of which were already in the specifications of the COLLINS class that emerged 30 years ago with a displacement of 3,100 tonnes, especially with regard to a performance capability suitable for non-nuclear missiles. Submarines extraordinary mobility: The required transit distances in intermittent snorkelling operation of 3,500 nautical miles each (17 days each) at 10 knots (!) from the Perth base in Western Australia suggest that the operational areas of Australian boats are seen in the marginal seas off China, the Indonesian archipelago and in the Indian Ocean as far as the Arabian Sea. In addition, there are approx. 4,000 - 5,000 miles of external air-independent, low-noise operation at 5 knots in the patrol area (35 days). Therefore, a required total range of 12,000 miles and a mission duration of approx. 70 days can be assumed, plus corresponding safety margins (e.g. 20 % residual fuel and residual reactants after return). Projected onto Germany, this would mean that our Submarines would have to be optimised for missions off the American east coast all the way to the Caribbean! A transit from the Perth base to Sydney alone is equivalent to a journey from Eckernförde to the Mediterranean. Objections from critics that such performance parameters actually require a nuclear propulsion system are not heard in a country whose energy industry manages without nuclear energy.

The FSM will require several large diesel generators (COLLINS 3x1,400 KW) and state-of-the-art lithium-ion batteries for the above-mentioned mobility parameters at a tactically acceptable snorkelling rate. For an AIP system such as the fuel cell, a reformer system for producing hydrogen on board is indispensable. Taking into account the space and weight factors for fuel and operating materials, charging and AIP units, weapons, signature-reducing measures and, last but not least, accommodation and supplies for the crew, it is clear that this will be a very large conventional submarine, the likes of which none of the envisaged European partners have built to date. Even the Japanese SORYU class, which displaces 4,200 tonnes when submerged, cannot meet the required range, sea endurance and transit speed.

If you look at the displacement of this twin-hulled boat of "only" 2,950 tonnes, which is an indicator of the "usable space" criterion, the reason becomes clear: 1,250 tonnes are ballast water!

It is a given that the US will supply the FWES and armament, as the RAN is more closely linked to the US Navy than any other navy thanks to the bilateral co-operation agreement of 2001 - and this is to remain the case. In this way, the Australian submarine force has virtually attained the status of a junior partner to the US Navy, with all the privileges that this entails. As with the "Replacement Combat System", with which the US Navy together with American companies helped 10 years ago to replace the COLLINS-class system, which had never been developed to a functional state, and to lead the boats out of the permanent crisis, the FSM will also receive an updated AN/BYG-1. This is the standard FüWES of the nuclear attack submarines (SSN), which was adapted for conventional submarine use in co-operation with the RAN. The Mk 48 torpedo and the Sub-Harpoon missile, possibly even supplemented by the option to deploy the Tomahawk cruise missile, will make the FSM a seamlessly interoperable platform with the US Navy.

Technical options and political trench warfare over the biggest submarine export deal of all time

For the reasons mentioned above, the Japanese will also not be able to offer an "off-the-shelf" design, but will have to come up with a new solution, presumably an evolutionary development of SORYU (literally "Blue Dragon"). Informed circles assume that Japan's KHI/MHI shipyards are already working on an upgraded SORYU variant, which will be called GORYU (literally "Australian Dragon"). At the end of 2014, it was announced that the last four of the 10-unit SORYU class - starting with the 2016 intake - will no longer be equipped as hybrid boats with Stirling AIP, but exclusively with lithium-ion batteries. It is obvious that the low efficiency and "bulkiness" of Stirling engines compared to fuel cells have not met operational expectations. For this reason, experts are watching with interest to see whether the GORYU design will also do without AIP, especially as the Japanese have not yet come up with a fuel cell suitable for submarines. The Japanese competitors already have one technical advantage over the Europeans: they have received approval from the USA to install the American FüWES.

The "J(apan) option", which has been considered as a candidate for SEA 1000 since at least 2012 due to the suitable boat size of SORYU, gained momentum in spring 2014 as a result of Prime Minister Abbott's visit to Tokyo and no longer poses a legal problem since Prime Minister Abe's government relaxed the rigid Japanese arms export ban by law on 1 April last year. The USA, interested in the realisation of a strategic tripartite alliance, supported the approach of the two prime ministers, according to informed sources.

In July 2014, Prime Ministers Abbott and Abe personally signed a bilateral defence framework agreement, which made a submarine deal appear politically feasible in principle. In addition, according to Abbott's message to the Labour opposition, realising the deal would make it possible to close the looming capability gap from 2025, which threatened to arise due to the delay in the submarine programme during the Labour years in government. The phrase "captain's pick", the deal between male friends, did the rounds. When President Obama held a trilateral meeting with Abe and Abbott on the sidelines of the G20 summit in Brisbane, the rumours about the American blessing for the submarine deal with Japan were given further impetus.

However, when it became clear shortly afterwards that Tokyo, as a newcomer to the export of large weapon systems, was expecting the hulls to be built in Japan and would at best agree to the boats being finished in Australia, Abbott had a problem: his election campaign promise that the FSM would be built at the domestic shipyard "Australian Submarine Corporation" (ASC) - as COLLINS had been - could not be kept under "Option J". The Labour opposition, the trade unions, the opponents of a SORYU deal in the active and retired submarine community and all advocates of maintaining the painstakingly built-up shipyard capacities gained the upper hand, the media fuelled the debates and the potential European competitors could hope again. When Defence Minister Johnston then made the lapse that he "didn't even trust ASC to build a canoe", he had to resign at the end of 2014. His successor Andrews rowed back, Abbott himself denied that a "captain's pick" had ever been intended and held out the prospect of a fair competition that was yet to be finalised, even if an open tender had to be avoided due to the time required over several years and the capability gap that would then be all the more imminent. The final result was the announcement of 20 February 2015 on the competitive evaluation process. This means that France and Germany are clearly back in the race.

France's DCNS submarine shipyard intends to fulfil the parameters with a non-nuclear version of the BARRACUDA class (approx. 5,000 t). The political support from Paris will in any case be as unscrupulous and efficient as usual, as the German submarine builders have already bitterly experienced in their defeats in India and Brazil.

But Berlin also seems to have realised that an arms deal with NATO-equivalent Australia is unlikely to have the potential for scandal that is always on call here in Germany. In any case, Chancellor Merkel was not above making it clear to her colleague Abbott at the Brisbane summit that the German government not only fully supported German industry, but was even "fighting for one of the largest arms export deals in German history", as DER SPIEGEL wrote in issue 5/2015. With regard to the Japanese competitor, Merkel also pointed out to the Australian prime minister that Germany could act in a politically neutral manner, while Japan was suffering from tensions with China. "You're right about that," Abbott is said to have replied; China is Australia's largest trading partner. Abbott's spokesperson declined to comment, but in the Australian media, a politics professor at the Australian National University (ANU) was quoted as saying that Dr Merkel had made an "astute" observation - which can be translated as "astute" but also "cunning" - and added: "By buying a Japanese Submarine there is a risk involved [because of China] that simply does not exist if you buy a German one".

In any case, Germany's TKMS will be using the type 216 the competitive evaluation process against BARRACUDA and GORYU. The design specially developed for the performance profile of SEA 1000 has already been in progress for 6 years and HDW presented it for the first time in April 2009 in response to the Request for Information (RFI) submitted at the end of 2008 under the then Labour government. According to the plans at the time, the structured process was to reduce the four purely European competitors to two at the end of 2011 and determine the winner of a "preliminary design phase" at the end of 2013, followed by the contractual design phase in 2016 and then the construction contract. This means that the evaluation competition now underway is "quick and dirty" in comparison and the overall project is "only" two years behind schedule thanks to this procedural trick. It can be assumed that U216 has been refined far more over the years than would be necessary for a rough draft, as is now required in the competitive evaluation process. The Germans therefore have no advantage over the French, as DCNS also received the same RFI, but they do have an advantage over the Japanese, who have to design GORYU under considerable time pressure.

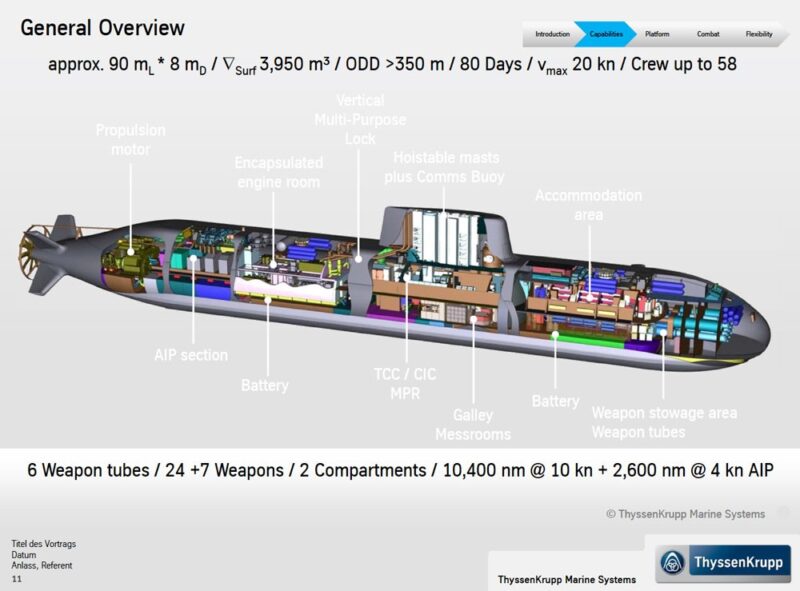

U216 is an impressive "paper submarine": 4,000 tonnes of surface displacement, lithium-ion batteries combined with Fuel cells-AIP and methanol reformer, a "Vertical Multi-Purpose Lock", which is just as suitable for loading various missiles as it is for transporting over 20 special forces or launching underwater drones. The boat has a crew of 34 and can accommodate up to 29 additional people. All mobility parameters are met and it can be assumed that it will be possible to obtain approval for the integration of American FüWES and weapons, especially as US armament has already been implemented in a number of German export boats from various recipient states. Long before the criteria for the evaluation competition were opened, the TKMS managing director, unlike the Japanese, had already stated during his visit to Australia in October 2014 that he saw no problem in building all boats at ASC, that this was possible for a fixed price of 20 billion $, that his company held all copyrights (IPR) to the design and that these would be transferred to Australia without restriction. With Japan, on the other hand, where the navy and not the industry is the "design authority" and where there is considerable resistance to any proliferation of the key submarine technology, the issue of IPR is likely to be far more difficult.

Lessons learnt from the COLLINS project - knowledge for the competitor

History does not repeat itself, but the parallels to the situation 30 years ago are worth a look at the young tradition of submarine construction in Australia.

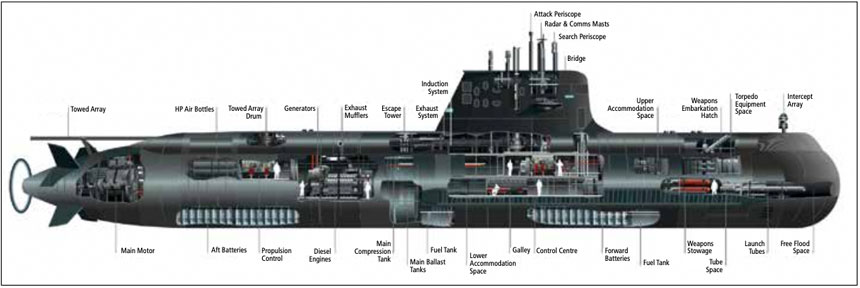

For informed Australians, the six COLLINS-class boats are synonymous with a defence disaster, which the media reported on incessantly. Planned since 1982, contracted in 1987 with the Swedish partner Kockums as designer and the newly founded South Australian shipyard ASC with considerable effort, they were put into service between 1996 and 2003. In fact, even during the construction and testing phase, they suffered from never-ending technical defects, supply bottlenecks, material defects and legal disputes between the intricately interwoven contracting parties. Defective weld seams on the first pressure hull sections still manufactured in Sweden, unstable diesel engines, vibrating periscopes, cracks in the propellers and unacceptable hydrodynamic noise phenomena were still comparatively easy problems to solve.

The real disaster was the American company Rockwell's FüWES, which, despite ten years of development, failed to produce an operationally usable result. The boats were not capable of using weapons. Worse still, it was a challenge for the crew to participate safely in maritime traffic, as safety-relevant systems such as sonar, periscopes and radar were integrated into the unstable FüWES. Only the complete replacement of the unsuitable system in the aforementioned collaboration with the US Navy brought the breakthrough by 2005, and the COLLINS class now largely fulfils the ambitious specifications.

"The COLLINS-Class Submarine Story" is the title of the excellently researched book by authors Yule and Woolner, published in 2008. Anyone who is planning a submarine project with the Australians today should be familiar with it. Reading it gives an idea of the "lessons learnt" with which the contract partners from "Down Under" will approach cooperation with foreign partners, which mistakes they will avoid and which positive experiences they want to repeat and above all: what they are justifiably proud of. They have learnt a lot, but COLLINS was already the most ambitious submarine project ever undertaken by a country without its own construction tradition. Newly established, virtually on a greenfield site, 1,500 highly motivated ASC employees delivered good work, as the problems described were mainly due to either (Swedish) design weaknesses or poor subcontractor performance. After all, in less than 14 years, the company had succeeded in building the world's 6 largest conventional Submarines and to put the first one into service 9 years after signing the construction contract.

Even if the Abbott government obviously favoured building out of the country with "Option J", it will probably not be able to push it through, because it is about preserving the submarine expertise that has been painstakingly built up, not only for construction, but also for maintenance and repair over the life of the new boats. And it's about jobs. Of course there are sceptical voices, those who want to spare the country a new "COLLINS story", because SEA 1000 means 25 long years of construction time for 12 boats, 18 years if it should only be 8 boats. But SEA 1000 also means that 1,500 of the current 2,400 employees at ASC, most of whom work in surface combatant shipbuilding, which will soon come to an end, could keep their jobs. TKMS would therefore do well to pay particular attention to the "build ashore" option in its offer.

Yule/Woolner explains the reasons why in 1987 the Swedish Kockums with its Type 471 was pitted against the German Type 2000 from IKL/HDW was awarded the contract: "... the Germans were too conservative in their design, and since the Swedes agreed to everything the Australians demanded, the Germans should have followed suit ... but the Germans didn't recognise this message ... they wanted to fulfil the basic requirements and win on price ... For Kockums, the potential deal with Australia meant saving the company, while for HDW was just one of many export projects."

The propaganda war over the contract for the SEA 1000 began a long time ago. The Japanese are accused of irreconcilable cultural differences and a lack of export experience, while the Germans are accused of never having realised such a large boat before. TKMS is well advised to spare no expense in order to stay ahead on the media front and secure strong political support. In 1987, the Swedes were also the better ones on this front and a traditionally Germanophobic British newspaper was able to headline unchallenged: "Deutsche Submarines sell like Japanese cars", which at that time still had a disparaging meaning and alluded to cheap and inferior mass-produced goods.

One thing is certain: whoever wins the SEA 1000 and is allowed to realise the FSM with Australia will dominate the non-nuclear submarine market until the middle of the century.

During the competition for COLLINS in 1986/87, Captain Wallner was a consultant for submarine armaments in Fü M VII. When SEA 1000 began in 2008, he was Head of Division for Underwater Systems in the Armaments Department of the BMVg and was involved in the official support of German industry.

Author: Raimund Wallner