Innovations and technologies of the third ECT

With the ceremonial commissioning of the task force provider (EGV) BONN on 13 September 2013 in Wilhelmshaven, the third EGV was handed over to the German Navy - externally similar to the first two sister ships BERLIN and FRANKFURT AM MAIN, but technically a clear innovation. A concept that has been tried and tested in service, further developed through technical progress, coupled with an economically optimised design and a consistent focus on the future tasks of the Bundeswehr and the German Navy - these are the characteristics of the new BONN task force supply vessel.

Task force provider

Task force provider provide logistical and medical support for mixed task forces at sea. Equipment, capabilities and crews ensure the comprehensive supply of fuel, fresh water, food, ammunition and supplies worldwide, around the clock and completely self-sufficient. This provides sustainable support for sustained participation in long-term global conflict and crisis management operations - in figures: One Task force provider extends the operational capability of a convoy consisting of four frigates from 21 to 45 days.

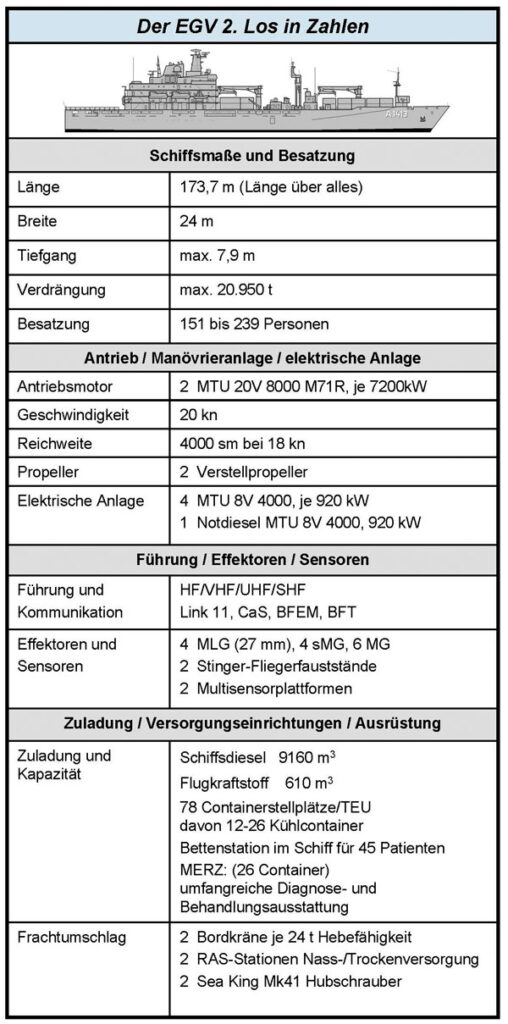

9,000 m³ of marine diesel, over 600 m³ of aviation fuel, 260 tonnes of ammunition, 125 tonnes of refrigerated and frozen goods and 100 tonnes of provisions can be transported - a huge "warehouse of materials and goods" is available worldwide thanks to the EGV. The fuels and goods can be transferred at any time on the high seas via two RAS stations (Replenishment at Sea), even simultaneously if required. Furthermore, 78 containers can be transported and delivered alongside using the two 24-tonne lifting cranes, independent of any port infrastructure.

In addition to the comprehensive logistical services, the EGV is characterised in particular by the medical care options available at the EGV. BONN have been significantly expanded again compared to the first two ships. There are now two treatment rooms and two sickrooms as well as a medical facility with 24 hospital beds on board the ship. In addition, a containerised Marine Emergency Rescue Centre (MERZ) with two operating theatres, a dental unit and a medical laboratory can be accommodated and operated. Such a high-quality "hospital at sea", combined with highly qualified medical personnel, guarantees optimum medical care at all times during operations.

With a speed of well over 20 knots at the EGV BONN and its comprehensive communication and command and control capabilities, the EGV is an integral part of a task force. Maritime surveillance, search, boarding and rescue missions as well as personnel and material transport over long distances are made possible by the operation of two Sea King MK 41 helicopters. In addition to the refuelling facilities for helicopters, the spacious helicopter hangar offers sufficient space and equipment for their maintenance and repair work. Safe helicopter guidance is ensured by a new helicopter guidance radar system, which will also be retrofitted on the first two ships.

Innovation

If you boil it down to a common denominator, the Task force provider multifunctional ships that have proven themselves time and again in a variety of applications and in a constantly changing requirements profile.

It is therefore not surprising that in mid-2013, the Canadian government decided in favour of EGV for the realisation of its two future joint support ships following an extensive selection process. The decisive factor for the award of the contract was that the concept of the German Task force supplier in terms of operational capabilities, operating costs and deployability.

Against the background of the German Navy's worldwide deployments with changing tasks, the increasing need for such multifunctional ships is becoming extremely clear. The fact that the design of the EGV as a multifunctional ship has proven itself and demonstrated its versatility is particularly evident when one considers that the ship design is based on the Military, Tactical and Economic Requirement (MTWF) from 1996. The fact that in a range of applications that has changed since then, the Task force provider The many successful deployments of the first two EGVs since their commissioning in 2001 and 2002 underline the fact that they have proven their worth. The reality of deployment clearly shows the change in requirements. The EGVs - originally conceived as an integral part of a task force - are increasingly being deployed as "lone wolves". The successful humanitarian aid provided by the EGV BERLIN after the tsunami disaster in South-East Asia has shown that such tasks can also be performed by the EGV. At the same time, however, single-operator missions require increased helicopter command and control capabilities, which are now provided by the helicopter guidance radar system. Another example of the changed operating conditions is the increasing duration of operations in tropical waters. When building the third EGV, this situation was taken into account by increasing the available cooling capacity, among other things. However, it is not only changing operational requirements that call for innovative solutions. The need for ever more economical operation, increasing environmental protection requirements, rising safety standards and, last but not least, the need to increase the attractiveness of operations in order to attract new personnel make innovations unavoidable. Engineering solutions, tailored to the needs of the Bundeswehr, were the basis for further development into the Task force provider BONN.

Technology

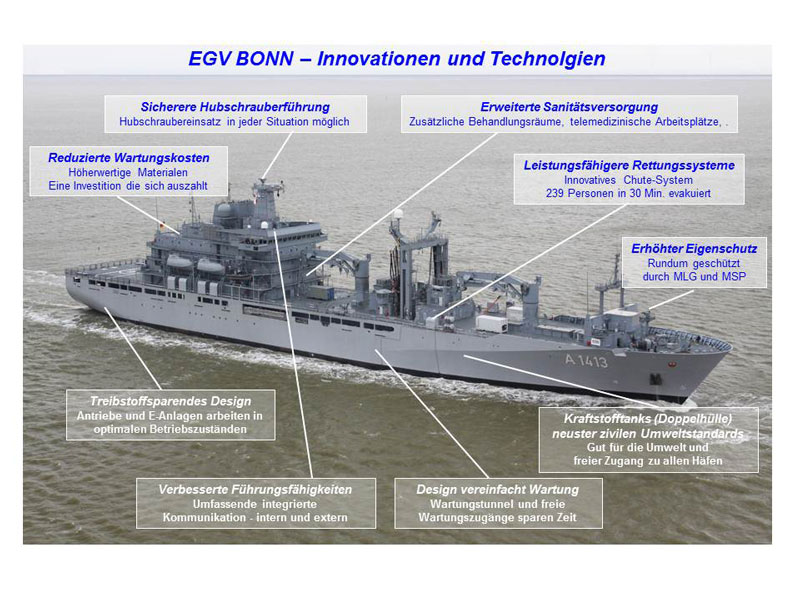

The fact that a proven concept can be adapted to changing requirements through technical progress led to significant changes, additions and optimisations in the areas of hull, propulsion, power generation, accommodation, rescue equipment, damage control, self-protection, command and control capability and technical documentation in the third EGV.

A selection of technological changes in the third EGV is intended to illustrate the variety of innovations that, taken together, represent the significant progress and potential of the EGV. BONN should show:

- When designing the hull, the current regulations of the ship classification society Germanischer Lloyd (GL) stipulate stricter design criteria. The implementation of these requirements leads to the EGV BONN to an increased load-bearing capacity of the ship's hull against sea impact.

- In order to better adapt the drive system to the EGV's driving profile with frequent load changes and a high proportion of light loads, the drive system, including the entire drivetrain, was completely redesigned. The two selected high-speed MTU 20-cylinder 20V 8000 M71R diesel engines with electronic common-rail injection, four turbochargers, an intercooler and cylinder deactivation each provide 7.2 MW, which is 35 per cent more drive power than the first batch. This not only significantly exceeds the required maximum sustained speed of 20 knots. Due to the favourable torque characteristics of the propulsion diesels, the controllable pitch propellers can already be operated at low speeds in the design pitch, which not only almost completely avoids vibrations, but in particular allows the propulsion system to be operated at its best efficiency.

- Five identical MTU 8V4000 M50B eight-cylinder diesel engines (also with electronic common-rail injection, turbocharger and intercooler) are used for power generation in combination with synchronous generators, each with a continuous electrical output of 875 kW, which are adapted to the expected power requirement and enable the lowest possible fuel consumption by being designed for the optimum load range. The use of five identical systems also results in economic advantages in utilisation through synergies in training as well as spare and replacement parts.

- State-of-the-art standards are used to accommodate the team. The functionally appealing equipment also includes, among other things, the provision of specialised electronic information via a fibre optic cable-based network "Betriebsführung Truppe (BFT)" to all chambers.

- The rescue equipment has been adapted to the current building regulations. The use of an innovative mass evacuation system in the form of a "chute system" (tube slide) for rapid evacuation, as used in civil shipping, should be emphasised. Furthermore, a second, additional fast rescue boat (FRB) will be deployed, which can accommodate up to 12 people and can reach top speeds of up to 35 knots.

- For the first time, a ship-wide, mobile TETRA-based (terrestrial trunked radio) radio communication system is available in the area of emergency response. This not only offers flawless communication with any connected subscriber, but also transmits important information about the condition of the person and their equipment. This means that a complete and comprehensive picture of the situation is available at all times and enables targeted command of the damage defence battle.

- Self-protection is ensured by equipping the ship with two multi-sensor platforms (MSP 600) with optical and thermal imaging sensors as well as four light naval guns (MLG 27 mm), four heavy machine guns (sMG 12.7 mm), six machine guns (MG3 7.62 mm) and two anti-aircraft guns. Shipbuilding precautions have already been taken to install a missile defence system.

- Various telecommunications systems, including several HF and VHF systems, are available as command and control equipment. They are used to transmit voice, write and data radio and LINK. They are controlled via an integrated message handling and control system (IMUS). Compared to the first batch, the capacities in the area of satellite communication have been significantly expanded. A SHF SATCOM and UHF SATCOM system as well as two Fleet Broad Band 500 systems and a KU band system are now available for this purpose. This enables LINK 11, Battle Force Email (BFEM), Collaboration at Sea (CAS) and extensive voice and text radio. The increase in command and control capabilities also includes the fact that on the EGV BONN an international command staff can be embarked. This can operate independently and separately from the ship and convoy command from three rooms set up specifically for command tasks.

- The scope of delivery for establishing supply readiness, both in terms of technical documentation and the scope of spare parts and replacement parts, is comprehensive and takes into account the current requirements of the German Armed Forces, including the SASPF (Standard Application Software Product Family) standard.

Realisation

When the construction contract was signed on 17 December 2008 by the then Vice President of the Federal Office of Defence Technology and Procurement (BWB), Reinhard Schütte, with the representatives of the EGV consortium (ARGE) Mr Lürßen (Fr. Lürssen Werft), Mr Sierk (Flensburger Schiffbaugesellschaft - FSG), Mr Kadow (Peene-Werft) and Dr Eckel (Emder Werft und Dockbetriebe - EWD), intensive preparatory work had already been carried out over many years. In addition to intensive negotiations with the consortium, the project management at BWB held intensive talks with the user, both with the EGV crews and with the utilisation management and the technical experts. This was the only way to find the optimum balance between requirements, technical solutions and costs - both for procurement and utilisation.

After an intensive design phase, the start of production of the third EGV was heralded on 23 March 2010 with the start of firing of the deckhouse at FSG in Flensburg. Three months later, construction of the hull began at the Peene shipyard with the first plate cut. On 16 August 2010, the keel was laid at the Peene shipyard by the then Minister of Defence as an important milestone in the practical realisation of the third EGV. The ship's hull was floated on 27 April 2011, and in May 2011 the hull and the deckhouse, which had been completed in the meantime, were transferred to EWD in Emden, where the "wedding" - the deckhouse being placed on the 174 m long hull with millimetre precision - took place on 31 May 2011. On 17 April 2012, in a ceremony attended by the Minister of Defence, the wife of the Lord Mayor of the sponsor town of BonnMrs Hanne Hufschmidt, the third EGV in the name of BONN. The final outfitting and the installation and integration tests then continued until the end of 2012, so that the first shipyard test run could be carried out in February 2013. The extensive proof of function finally led to the acceptance of the EGV on 26 June 2013 BONN and its commissioning on 13 September 2013 (see MF 11-2013 p. 12ff).

Summary

With the successful realisation of the EGV BONN The efficiency of both the public client and the German shipyards and supply industry was demonstrated. The results to date from the functional and performance tests, which have now been ongoing for over six months, have confirmed the expectations of this ship - even with the participation of the military crew. With the Task force provider BONN the German Navy will receive a mission-orientated and future-proof operational asset that will further strengthen the Bundeswehr's maritime capabilities in the long term.

Gunther Brückner is Technical Government Director and Head of Division S5.1 at the Federal Office of Bundeswehr Equipment, Information Technology and In-Service Support (BAAINBw)

Author: Gunther Brückner