Many of the German Navy's missions involve asymmetric threat in the foreground. Modern protection systems promise safety.

The German Navy has been operating in crisis regions around the world for many years in order to contribute to their management and to securing sea routes. In this environment, naval units are exposed to a wide range of threats during operations in coastal waters, straits and harbours. In addition to traditional threats, the ships are particularly exposed to asymmetric and hybrid threats. Asymmetric threats have become increasingly serious since the end of the 1990s. This was demonstrated above all by the attack on the destroyer USS Cole on 12 October 2000 in the port of Aden. While the Cole was bunkering fuel, a boat loaded with explosives went alongside and exploded. Seventeen crew members lost their lives and the destroyer was badly damaged.

In naval operations, the ability of the units to assert themselves and, above all, to persevere across the entire spectrum of maritime operations is crucial. The ability of the units to protect themselves is an essential prerequisite for this. Ship protection systems include, in particular, armour in the form of Protection technology.

Suicide bombers, pirates, terrorists and other non-state actors attack ships with small and medium-calibre hand weapons, shoulder-launched grenade weapons and, more recently, with small drones carrying explosive charges. Armouring sensitive areas of the ship with special plates made of a lightweight composite structure offers quite good protection against this. This additional layer is necessary because the shipbuilding steel used today is only seven to nine millimetres thick. This comparatively thin skin offers hardly any protection against bullets. Composite plates, on the other hand, are generally 15 times more effective than shipbuilding steel. For this reason, numerous units of the German Navy have now been retrofitted or equipped with protective plates. The four future Class 126 frigates are also to be equipped with corresponding protection technology.

Sensitive ship areas are protected against asymmetric threats on the F 126

Competence and expertise

In over 30 years, Geke Schutztechnik GmbH has acquired extensive expertise in the development and manufacture of Protection technologies build. The subsidiary of FFG Flensburger Fahrzeugbau GmbH has also equipped various Bundeswehr combat vehicles, such as the Leopard tank, the Marder and Puma infantry fighting vehicles, the Boxer wheeled armoured personnel carrier, the Fenek reconnaissance vehicle, the Dingo transport vehicle and the 2000 self-propelled howitzer with protective plates. The vehicles were fitted with specially developed all-round ballistic protection. The roof was protected against artillery fire and bomb fragments, the sides against shaped-charge projectiles and gunfire up to 120 millimetres, the floor against mines and explosive devices and the interior with so-called liner plates against projectile fragments and splinters.

Ballistic protection plates are based on composite structures that combine the advantages of different materials. These are materials that have to withstand highly dynamic stresses. The individual material layers can consist of steel plates, ceramics, high performance polyethylene (HPPE) or synthetic fibres such as aramids or nylon, and are hybridised, i.e. bonded or vulcanised to form active and passive protection systems in order to achieve reliable bonding between the different materials.

As part of the ongoing development of the Protection technologies Geke Schutztechnik has acquired a patent for hybrid and reactive armour that neutralises incoming projectiles before they hit the target. The principle of reactive armour is based on an explosive material being bonded between two plates. If a shaped charge jet hits the explosive, it reacts and hurls the upper plate towards the jet. This causes the jet to disintegrate, losing its penetrating power and destructive effect.

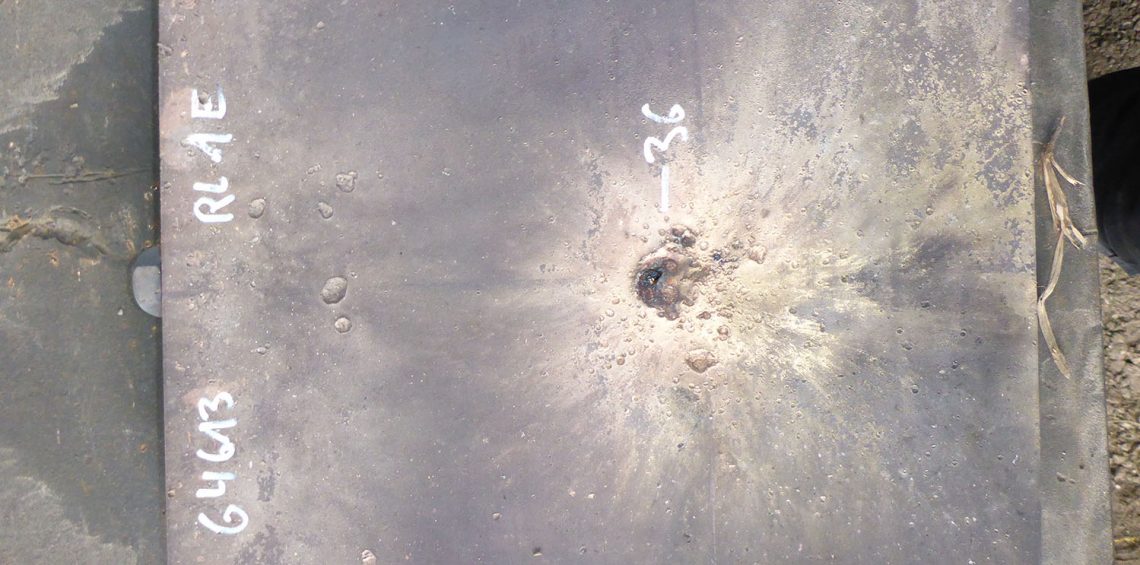

In collaboration with the Weapons and Ammunition Technical Centre (WTD 91), which has the largest instrumentalised firing range in Western Europe, 247 tests, simulations and analyses with shaped charges were carried out and numerous studies were conducted to verify protection against various projectiles. Finally, the continuous further development of the products has made it possible to develop new panels with greater protection and lower weight at the same time.

Penetration power of a shaped charge after disturbance of the hollow charge jet by a passive buckling plate structure

Maritime Protection technology

The new models developed for land vehicles Protection technologies can also be used on naval units. Geke Schutztechnik has systematically worked on the transfer to the naval sector and carried out numerous successful experiments with ships. For reasons of stability and weight, pure steel armouring is not an option for many ship areas. For this reason, new materials and protection systems are increasingly being used to provide ballistic protection for these areas. The fact that the latest generation of protective plates can boast a weight reduction of 40 per cent is of particular benefit to the marine sector. Overall, however, ballistic Protection technology of the land vehicles must be adapted to the special requirements of the navy. These include high resistance to the effects of moisture and salt. Surfaces on naval vessels are also significantly larger than on land vehicles. Other distances, greater space requirements and a lower weight of the protective panels must therefore be taken into account. Geke Schutztechnik has already created pioneering new developments for the marine sector and can therefore offer market-ready protection solutions.

Text: Dieter Stockfisch, Photos: Damen, Geke

0 Kommentare