At the beginning of May 2023, the Hvide Sande shipyard on the Danish west coast handed over the first offshore patrol vessel (OPV) to the Danish Fisheries Agency. It was delivered with azimuth propulsion nacelles and in combination with a guide plate (hull vane) under the stern.

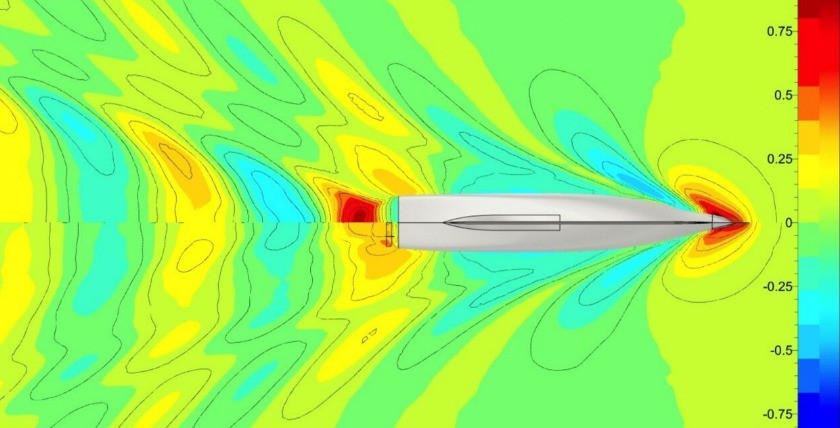

A hull vane smoothes out the turbulence behind a moving ship and makes it faster and quieter, i.e. more efficient. At the same time, the sea behaviour is improved. For the development and function of a hull vane, see the article "Netherlands: Hull Vane for the GRONINGEN" from 12 February 2023.

Danish OPV Nordsøen operates with reduced wave formation. Photo: HullVane/T.Sund

Target formation

The public tender emphasised low life cycle costs and energy efficiency. Hvide Sande Shipyard therefore cooperated with the Dutch company Hull Vane BV as early as the design phase. The "Nordsøen", 64 metres long and weighing approx. 1300 tonnes, usually travels at speeds between 10 and 18 knots. A Hull Vane should certainly offer advantages here.

Innovations

A hull vane was installed on a ship with diesel-electric pod propulsion for the first time. Diesel generators feed the electric motors suspended in pods under the hull with their propellers. The nacelles, which can be rotated to a limited extent, also take on the function of the rudder blades. All in all, this is a propulsion system that has probably never been tested with a hull vane before, but it seems to make a lot of sense.

Another new feature in combination with the Hull Vane is the ramp system for a dinghy: a ramp for the small boat is extended via a flap in the stern - the stern should not be submerged too deeply, but should remain stable in the sea even in swell - absolutely matching the guide plate below.

Practical test

Calculations with and without hull vane confirmed a drag reduction at 10 knots of 12 %, at 14 knots of 17 % and at 18 knots of 14 %. The "Nordsøen" actually produced a lower noise level during the sea trials and caused only a small wave system at all speed levels, especially in the stern sea. This is a clear sign of more even flow conditions around the ship and better efficiency of the propulsion system. As calculated, CO2 emissions can be reduced by 1000 tonnes per year compared to a conventional ship design.

Danish OPV Nordsøen. Photo: HullVane

Amortisation

According to the operating profile, the Hull Vane on the "Nordsøen" not only saves 300 tonnes of marine diesel per year. Due to the lower resistance of the ship, smaller azimuth pods were required to achieve the same speeds. These in turn have a lower power consumption and therefore enabled a smaller diesel generator system. All these savings exceeded the cost of the Hull Vane and thus reduced the overall construction costs. This meant that the investment in a hull vane had already paid for itself before the ship had even travelled its first nautical mile.

Energy transition at sea

Hull Vanes have now been installed on many patrol vessels in the Netherlands, Denmark, France, Belgium and Nigeria. On all these ships, the reduction in fuel consumption is over ten per cent, making it a proven and cost-effective solution.

Perhaps shipbuilding engineers in Germany should also take up this topic, as it offers plenty of potential.

Source: SWZ|Maritime, Rotterdam, NDL.

0 Kommentare